R-Mark Certification: The Ultimate Guide to Getting RMI Certified

Interested in working with an R-mark certification manufacturer? Or maybe even getting certified yourself? Working with an R-mark certified manufacturer gives you a wealth of assurances that your project is going to be done right. Getting certified means that your rack is able to hold up to the high standards of the RMI. In this…

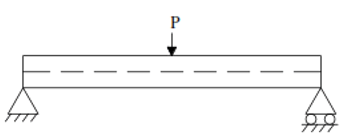

Point Load vs. Distributed Load

Although it may seem trivial, the type of load has just about as much of an impact as the magnitude of the load. You may have heard the terms “point load” and “distributed load” before, and in this article, we are going to address them both and how they apply to our industry. These differences…

Pallet Racking Weight Capacity: How to Calculate It

Accurate assessment of pallet rack capacity is crucial to ensure a safe warehouse. Unfortunately, many overlook its importance or use oversimplified methods that don’t take into account all of the necessary factors. The repercussions of which can be far-reaching, leading to permit delays, inefficient storage practices, accidents and potential legal consequences. This article aims to…

What’s the Difference Between a Digital Seal and an Electronic Stamp?

When permits are required for a project, we all know that the plans are required to be stamped by a professional engineer. We’ve all experienced when a jurisdiction requires “wet stamped” plans versus an “electronic stamp”, but what about when the jurisdiction requires a “digital seal”? That’s the same thing as an electronic stamp, right?…

Storage Rack Software

Storage rack software helps you design structurally sound storage rack prelims. These programs not only get rid of guess work and empower the user to design their own rack, but they can also drastically speed up the rack design process. Good storage rack software helps you tell if your rack design is failing or passing.…

Utilization Ratios in Structural Engineering

You may have heard the term used before and been confused, but “Utilization Ratio” isn’t a complicated concept. Although it’s a structural engineering term, it also applies to the material handling industry and pallet racks. In this article, we’ll explain what it is, when and where it’s used, and how it’s determined. What is Utilization…

Overturning Ratios: How They Work

The overturning of pallet racks is a crucial concern in warehouse safety. The Rack Manufacturers Institute (RMI) ANSI MH16.1 sets standards for this, notably the 6:1 and 8:1 overturning ratios. These ratios indicate how stable a rack should be during regular use. However, seismic events add another layer of risk. Neglecting these factors can lead…

Storage Rack Design Guidelines: How to Create an Efficient System

Appropriate design storage rack systems greatly affect the operability of your warehouse. Poor storage rack and warehouse design can lead to reduced efficiency, increased risk of accidents, and potential financial losses. With a poorly designed layout, your labor force could spend unnecessary time traveling to pick/load spots. With improperly designed racks, you could experience damage…

Drive-In Racks: Are They the Right Storage Solution for Your Project?

Many warehouse managers struggle with optimizing storage space while ensuring easy access and inventory management. Drive-in racks have gained prominence for their ability to solve certain storage problems. This article will help you figure out whether they’re right for you. We’ll cover what drive-in racks are, their components, their advantages and disadvantages, and best practices…

Flow Racks: Are They Right for My Project?

In warehousing and logistics, it’s crucial to optimize space, efficiency, and labor costs. If you have specific requirements for storage, flow racks can be extremely helpful. These systems offer a unique approach to storage, capitalizing on the principles of gravity to streamline the movement of goods within a warehouse. In this article, we talk flow…